What is MFC

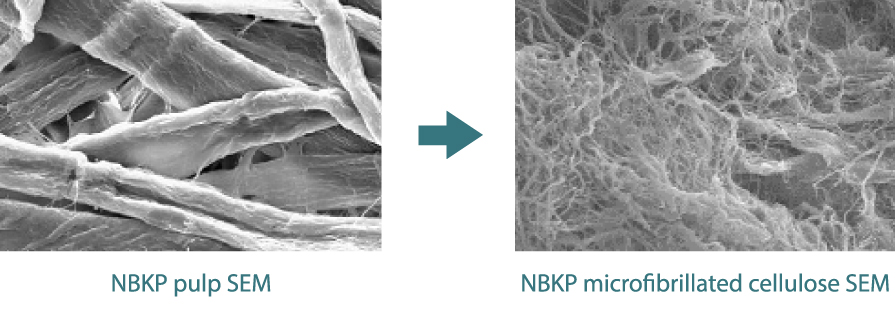

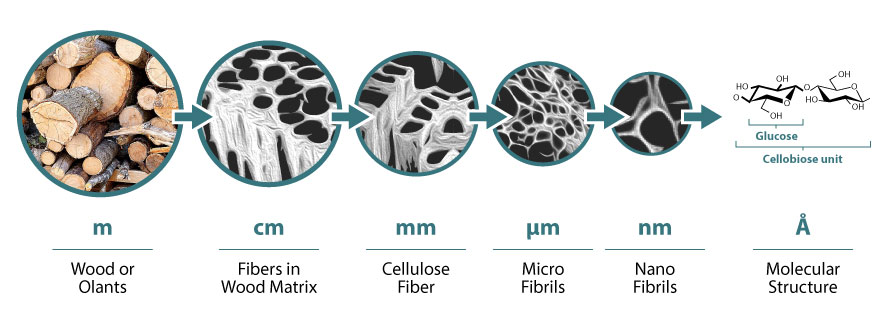

Cellulose fibers are built up of fibril bundles, which consist of smaller elements called microfibrils. Through a fibrillation process, the cellulose fibers are converted into a three-dimensional network of microfibrils with an ultra-high surface area. These microfibrils are called Cellulose fibrils / Microfibrillated Cellulose (MFC).

As a result of the fibrillation process, many hydroxyl groups become accessible to matrix in a network, resulting in a very high water-retention capability. MFC will also retain its crystallinity features after the production process, providing a robust product.

The field of Microfibrillated Cellulose (MFC) has been known since the early 1980s and has been reported several times in literature. Research on MFC has previously been confined to small laboratories and pilot plants, due to constraints in technology and production feasibility. Through its proprietary technology, S&C is now able to provide high quality Microfibrillated Cellulose (MFC).

Micro brillted Cellulose, Cellulose Fibrils or Nanocellulose

Cellulose fibrils is a new innovation, from bio-refineries and research institutes, where cellulose fibers are fibrillated (meaning that the mother fiber is split into a higher number of thinner fibers/fibrils). This creates an increased surface area giving the novel fibril product new characteristics. The product is typically sourced from softwood and hardwood sources, as well as vegetable sources. Thus, it is one of the most sustainable alternatives on the market. The fibril is in most instances a hydrophilic material, and is thus best suited in water based/water borne systems. It can act as an advanced rheology modifier, spraying characteristics and an unusually high viscosity at rest. By its physical presence, it has shown its potential as a potent stabilizer of solid systems.

What is the difference between micro-and nanofibrillated cellulose? What about cellulose nanocrystals and cellulose fibrils? They are not totally established, so the same material can have different names or the same terms can be used for very different kind of materials.

MFC is produced by mechanical treatment with or without enzymatic or chemical pre-treatment. The material consists of long and thin fibers which form a three-dimensional network, and these fibers have crystalline and amorphous regions. MFC has high viscosity and yield stress. The size distribution of the fibers is wide, and even if some fibers have diameters in nanoscale, there are a lot of bigger fibers as well. Moreover, the fibers are in a network structure and interconnected to each other.

It is also possible to produce similar material as individual fibrils, with nanoscale diameter and narrow size distribution, if special separation methods or chemical treatments are used. The term nanofibrillated cellulose (NFC) or cellulose nanofibers (CNF) is often used since the material is more in nanoscale than microscale.